Products

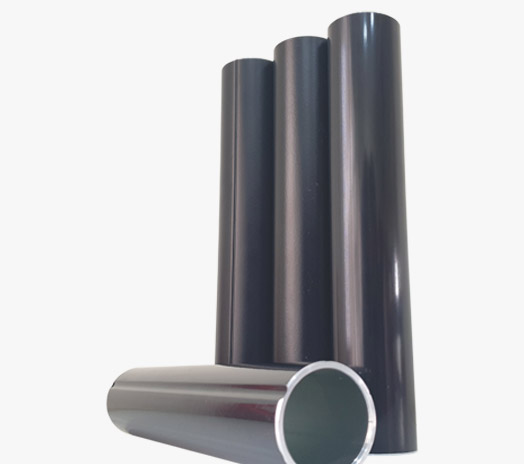

Aluminium Cheese Pipe

Cheese Pipes are used in large numbers in woven sacks unit to wind /warp bobbins. This inexpensive item often escapes the attention that is deserved while procurement. Cheese pipe is known by different name throughout the world such As MS Bobbin, Cheese Bobbin, Heart Line, Tubular, Cheese Pipe, Etc

Aluminum Cheese Tubes by AARAV INDUSTRIES are to be dimensionally accurate, light on the winders to save electricity, strong to withstand shrinkage and to be color coated to respond to color sensors installed in the looms to control wastage.

Special sizes can be developed to suit special requirments

Sizes Available

| ID (mm) | OD (mm) |

|---|---|

| 110 | 120 |

| 90 | 102 |

| 90 | 99 |

| 90 | 98 |

| 82 | 90 |

| 80 | 88 |

| 76 | 82 |

| 35 | 40 |

Dimensional Accuracy

Aluminium Cheese Tubes by AARAV INDUSTRIES are manufactured to maintain an ID / OD tolerance of 0.25mm and a length accuracy of 0.5mm with all other parameters as per standard specifications.

Tensile Strength

Aluminium Cheese Tubes by AARAV INDUSTRIES are designed to function against the phenomenon that woven sack units observe where their Cheese Tubes collapse in a very short span and frequent straightening is carried out which involves substantial manpower, money and time. Cheese Tubes tend to bend due to its low tensile strength.

Color Coating

The looms are fitted with the color sensor to reduce the waste. For easier identification in the end user's process, customized color coding can be provided on request. To increase the sensitivity of the color sensor, our tubes are powdered coated in AkzoNobel Approved powder coating plant or color anodize as required by customer to give an additional durability without compromising the mechanical and functional properties.